Non-standard automation is called the blood in the enterprise

The design of non-standard machinery is based on the samples provided by customers or the requirements. I believe there are still many people who are unfamiliar with this word, and when I mention it, I only know what it is. Then, I will make a simple science popularization for you. What are the non-standard mechanical designs? Features.

Features of non-standard mechanical design services:

1. Pay attention to the principles of design standardization, modularization and simplification.

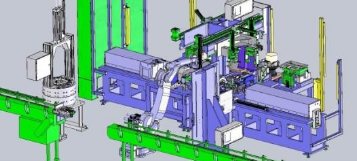

2. After the design is completed, you can export the product renderings in BMP and JPG formats for editing product information and making product advertisements.

3. All two-dimensional structural drawings are automatically generated by the computer according to the three-dimensional digital model, which ensures the accuracy of views and dimensions, and ensures the harmonious unification of drawing quality and work efficiency.

4. All 3D design software such as CAD and Pro / E are used to design products. The volume, weight, and center of gravity of the part can be generated, which provides a reliable basis for related design and subsequent processing.

Non-standard mechanical design field

The mechanical design is only designed and manufactured according to the given scheme and objects. The design of non-standard machinery is different. It has to be innovative. The design of non-standard machinery is designed without reference objects. Non-standard products cannot be replaced, but they can be gradually perfected and become standard products.

Non-standard mechanical design advantages

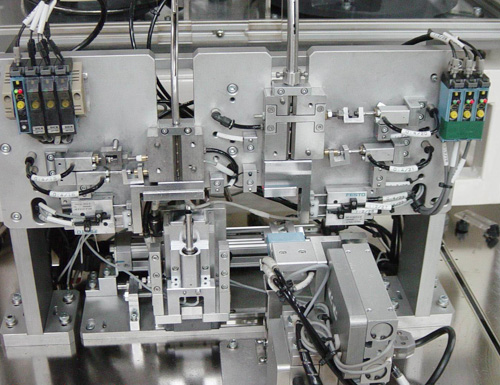

It can not only improve quality, but also improve efficiency, and it can also ensure production safety. So it is not controversial to bring the gospel to business. The design of non-standard machinery is customized according to the needs of the product, which can improve the product quality and complete a variety of complex labeling at one time, greatly improving the work efficiency, which can be operated by one person, reducing the number of stations, saving labor costs, simple operation, The product needs to be placed in the device. Just press the start button. Can guarantee the processing accuracy, and secondly, loading and unloading is convenient, accurate and fast.

Non-standard mechanical design prospects

The prospect of non-standard mechanical design has always been good. The technological progress of manufacturing cannot be separated from the non-standard design work. In the enterprise, it is the blood of the enterprise, and in the society, it is the vanguard of technological progress. Simply speaking, non-standard mechanical design is the design of non-standard equipment, non-standard parts, and non-standard tooling.

In the machinery industry, machine design is especially important. So what is the main job of non-standard automation designers?

If you do these 8 points, then you can become a qualified non-standard automation designer!

1. Organize the data: Learn all the details of the original production process in detail, and the existing capacity, labor quantity, quality, process, raw and auxiliary materials, etc.

2. Analyze the requirements: understand the main objectives and requirements from the client's supervisor;

3. Confirmation plan: According to the above two basic conditions, combined with alternative conditions, propose a preliminary feasibility plan and deliver it to the customer for confirmation;

4. Select the main components: After the feasibility plan is confirmed by the customer, the selection of the automation department begins;

5. Parameter verification: According to the customer's requirements for production capacity, carry out the design of the process steps of the entire process, and check and confirm the function of the selected automation components;

6. Make a reasonable design: After the above work is completed, you can carry out the design of the general assembly sketch and enter the normal mechanical design workflow. At the same time, electrical engineers and programmers will design and compile electrical schematics and program control software based on the overall implementation plan and process flow diagrams;

7. Audit and customer confirmation: After completing mechanical design, outsourcing automation components, mechanical processing parts, electrical diagrams and program-controlled drawings, after standardized review and customer confirmation again, manufacturing, assembly, and commissioning can be completed. After entering the trial operation phase;

8. On-site debugging: After trial operation and testing, after the design requirements can be met and the customer's requirements can be achieved, it can proceed to the customer's on-site installation and commissioning stage. Until the entire project is completed.

The above eight main aspects of the work are the basic operations of a non-standard automation staff, which must be carried out in strict accordance with the work specifications. Only in this way can the company develop better and be more appreciated by the boss.