From the machine tool industry to see Japan become a manufacturing powerhouse

As a defeated country in World War II, how did Japan rise from the ruins in just a few decades and establish a world-class industrial power? Let's take a look at the development history of Japanese machine tools.

Japan is the third country in the world to establish a machine tool industry, manufacturing industry, and industrialized power after the United States and Germany. In 1889, the Ikebei Iron Factory in Japan was established, and production of the first machine tool began. The machine tool industry entered the budding period. At this time, the government focused on vigorously supporting the machine tool industry, and made the machine tool industry as a manufacturing industry, and even the focus of the entire national economic development, in terms of policies and policies. In terms of strategy, it has proposed the establishment of a country based on science and technology, and a country based on trade; on the tactics, based on the machine tool industry, the iron and steel industry, the automobile industry, the power industry, the shipbuilding industry, the electronics, the nuclear power industry, etc. are developed. Since 1982, the strength of the Japanese machine tool industry has long ranked first in the world. Become the world's recognized machine tool industry, manufacturing, industrialization powerhouse.

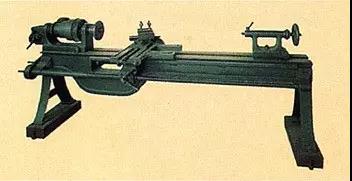

The first Japanese-made lathe

The Japanese machine tool industry has been in three major stages of technological development since the construction of the Ibei plant in 1889 to 122 years. The first stage (1889 ~ 1955) mainly produces manual ordinary machine tools. The second stage (1956 ~ 1976) is mainly to produce a variety of high-efficiency automated machine tools and automatic lines in accordance with the development needs of manufacturing industries such as automobiles, bearings, and motors. In 1974, the country surpassed the United States with 6,700 automatic lines. The third stage (1977 ~ 2011), mainly produces small and medium-sized automatic CNC machine tools. Due to its high flexibility, large automatic lines, and its wide application, the demand for CNC airports worldwide has increased dramatically. Its output surpassed that of the United States in 1978 (7,342 units in Japan and 5,688 units in the United States).

Since the output of Japan's CNC machine tools is leading in the world, its machine tool output value surpassed West Germany (US $ 3.748 billion) and the United States (US $ 3.745 billion) in 1982, starting to rank first in the world with US $ 3.79 billion. Subsequently, the output of CNC machine tools in Japan increased rapidly, and the output value of machine tools continued to rise until 2007, the year before the world economic crisis in 2008. Its airport output value strength has been ranked first in the world among 26.

In the above three major stages in Japan, the machine tool industry has fluctuated with changes in domestic and foreign situations, and has experienced many ups and downs. From this, it can be seen that the correct policies, policies, strategies and tactics are of great importance to accelerate the development of the machine tool industry.

The first stage

After the construction of the Chibei plant began in 1889, the Japanese-Russian war broke out in 1904. There are a large number of military products that are in urgent need of machine tool production and supply, which has greatly stimulated the development of the Japanese machine tool industry, manufacturing industry, and industry.

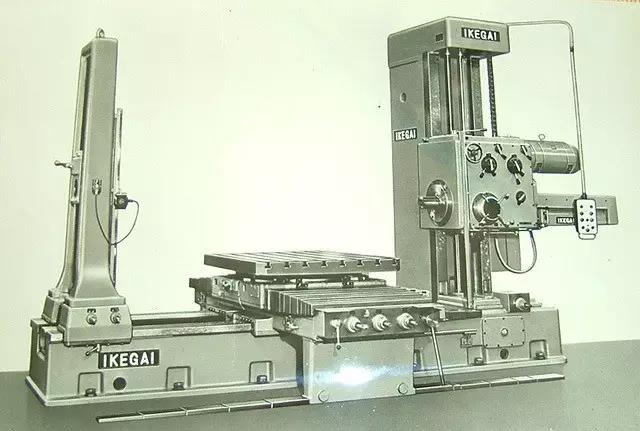

Immediately after the Second World War (1914 ~ 1918), Europe and the United States were busy participating in the war. Japan took the opportunity to develop the machine tool industry. Orders were busy, the number of factories surged, and the strength of the machine tool industry increased. Between 1914 and 1917, the number of employees in machine tool and parts manufacturing in Japan doubled (from 2,160 to 4,695). Technically, it has been able to manufacture large-scale machine tools, automatic lathes, and gear machine tools.

Early production of horizontal boring and milling machines

In May 1934, initiated by large companies such as Ikebei, Niigata, Okuma, Karatsu, the "Japan Machine Tool Industry Federation" was established to achieve mutual assistance in technology and put forward some requirements and suggestions to the government. In April 1938, the Japanese government promulgated the "Machine Tool Manufacturing Business Law", which included the machine tool industry within the policy scope and vigorously supported it. Preferential in terms of funds and taxes, and give necessary financial subsidies. The number of machine tool companies grew from 397 in 1932 to 1978 in 1938, and the total number of employees increased from 4100 to 63,000. The annual output of machine tools increased from 5,000 to 67,300 units. Due to the expansion of the strength of the machine tool industry and manufacturing industry, Japan launched the war of aggression against China (1937 ~ 1945). During the war of aggression against China, the machine tool industry produced military products and the number of employees soared to 126,000.

Wonderful sharing:

We specialize in the production of precision machine parts, mechanical parts,precision machining, OEM machinery parts,cnc machining,cnc milling,cnc turning parts.

If you have any mechine parts needs, please contact us:contact

If you want to see more CNC precision products, please click here: Product

If you want to see more news:News

Check out the latest company news on Twitter:twitter:@QianJmechanical